In the material storage sector, circular steel silos have long dominated. Their durability and affordability have made them widely used for storing bulk materials such as cement, grain, powders, and ore. However, with the increasing scarcity of industrial land and businesses' increasing demands for efficient space utilization, logistics, and economic returns, a more modern storage format is rapidly emerging: the square steel silo (or square silo). Square silos not only offer breakthroughs in design and structure compared to traditional round silos, but also fully meet the diverse material storage needs of modern businesses in terms of performance, flexibility, safety, and affordability.

What is a square steel silo?

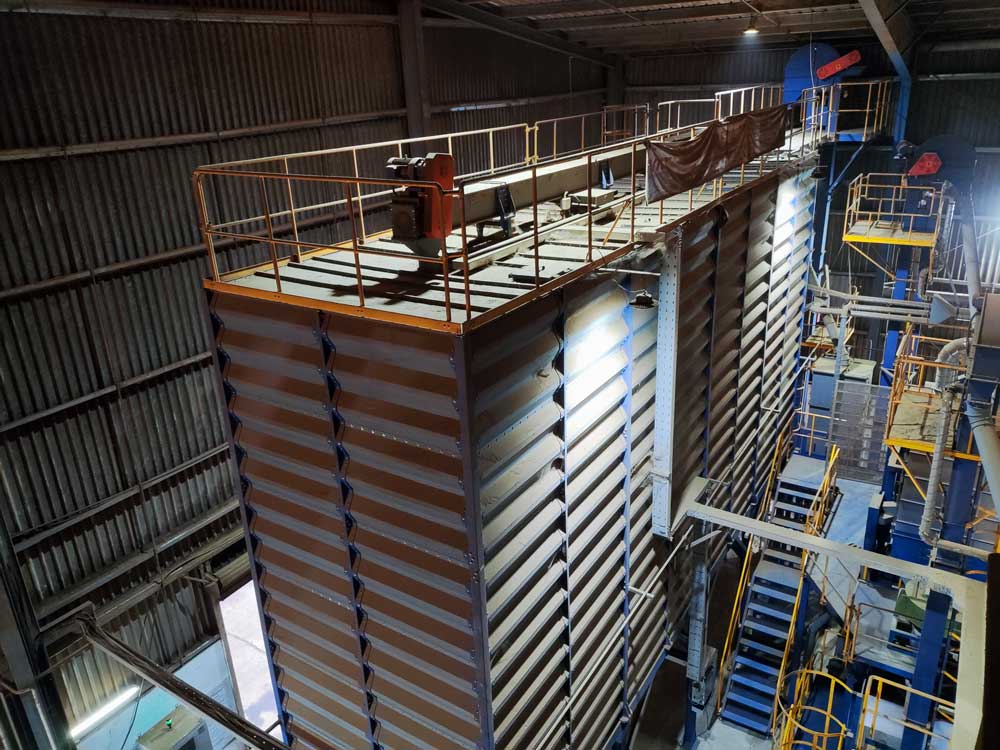

A square steel silo is a modular, square structure assembled from galvanized or stainless steel sheets. It is used to store grain, feed, granular, or powdered materials. Compared to traditional round silos, square silos offer larger storage capacity and a more compact, efficient, and flexible layout design. They also excel in structural strength, sealing, and expandability.

The versatility and flexibility of square steel silos make them a preferred solution for a wide range of industries:

Agriculture and food processing: storage of grain, seeds, rice, and coffee beans

Feed and livestock: compound feed, premixes, and pet food

Food industry: nuts, dried fruit, sugar, flour, etc.

Chemical and manufacturing: plastic granules, chemical powders, and environmentally friendly recycled materials

New energy and environmental protection: solid waste treatment and storage of renewable granular materials

Features of Cube Silo Storage

1. Maximized Space Utilization

Traditional circular steel silos, due to their circular structure, cannot be tightly joined together, often creating numerous triangular "dead corners" between silos. This land cannot be effectively utilized. This waste of land is particularly costly in areas where land is at a premium, such as industrial parks and port terminals.

Square steel silos, on the other hand, can be arranged closely side by side like "building blocks," seamlessly connecting to form a continuous storage array. This layout significantly increases the effective storage capacity per unit area, providing approximately 25% more storage space than circular silos. This is undoubtedly an attractive solution for companies facing limited land resources.

Furthermore, the square modules of the square silos can be easily integrated into existing structures such as factories and warehouses, achieving optimal space allocation.

2. Modular Design

Square steel silos utilize a standardized, modular design, making them not only quick and easy to install, but also flexible and adaptable to meet the company's specific needs. Users can initially build a number of square silos to meet current production needs. As production capacity increases, they can easily expand capacity by simply adding modules. This feature greatly facilitates a company's long-term development planning and the upgrade and renovation of its warehousing systems. For example, a feed mill may initially require only a few hundred square meters of storage capacity, but as production capacity grows, it can achieve material storage capacity of thousands of square meters or even larger by assembling new square silos.

The modular structure also makes transportation, lifting, and maintenance easier, reducing overall project cycle time and labor costs, making it a crucial component of modern intelligent warehousing systems.

3. Efficient Material Flow

Square steel silos also demonstrate extremely high operational efficiency in material unloading and conveying. Due to the curved surface of a circular silo, material easily accumulates on the walls and floor, resulting in unloading difficulties or even blockages. The square silo's right-angled walls and tapered bottom effectively avoid accumulation in these "dead corners," allowing material to fall and exit smoothly, significantly improving unloading efficiency.

Square silos also facilitate integration with various conveying equipment (such as belt conveyors, screw conveyors, and pneumatic conveying systems), enabling automated and continuous logistics operations. For manufacturers with high-frequency inbound and outbound inventory, this translates to higher operational efficiency and lower labor costs.

4. Superior sealing and moisture resistance ensure material quality

Sealing performance is a key indicator for evaluating the quality of storage equipment. During the manufacturing process, square steel silos utilize high-precision sealing strips and advanced welding techniques to effectively isolate external moisture, rainwater, and pests, significantly reducing the risks of mildew, caking, and insect infestation.

For materials sensitive to the storage environment, such as grain, coffee beans, and flour, excellent sealing is crucial for ensuring product quality. Furthermore, square silos can be equipped with intelligent features such as continuous material leveling, ventilation and cooling, and dehumidification systems, enabling businesses to achieve real-time monitoring and precise management of material conditions.

5. Sturdy, safe, and reliable structure, adaptable to various extreme environments

Utilizing high-strength galvanized or stainless steel sheet materials, combined with reinforced corner structures, a stable support frame, and a scientifically designed load-bearing structure, square steel silos offer excellent load-bearing capacity and wind and earthquake resistance. Whether in inland plateaus, coastal high-humidity areas, or the low temperatures of northern China, these silos operate safely and stably. While meeting local building codes, the silo also supports customization with various taper angles (40°/60°), multiple outlet options (side, bottom, and center), and tripod structures, providing highly adaptable support for diverse project scenarios.

6. Lower construction costs, simpler operation and maintenance, and greater long-term savings

Compared to traditional round silos, silo-shaped steel silos, with their standardized, modular design and flat-pack transportability, significantly reduce transportation, installation, and labor costs. They also offer a shorter construction cycle and faster overall commissioning, making them ideal for businesses with demanding storage system launch times.

Additionally, silos offer a simple structure and easy maintenance, requiring virtually no maintenance during operation. They offer extremely low lifecycle operation and maintenance costs, making them a cost-effective material storage solution.

In the tide of green, efficient, and intelligent development, rectangular steel silos, with their comprehensive advantages such as superior space utilization, modular and flexible expansion, efficient logistics operations, and reliable security, have become a key choice for modern enterprises upgrading their material storage. They are not only a replacement for traditional warehousing facilities but also a solid foundation for enterprises to achieve high-quality development, digital operations, and sustainable strategies. Choose rectangular silos to confidently meet challenges and usher in a new era of warehousing!

.jpg)

.jpg)