In the grain storage and transportation industry, particularly for rice, owners face three main challenges: first, micro-cracks inside the rice grains caused by impacts from falls from heights; second, localized stress damage resulting from deep static pressure accumulation; and third, secondary breakage during dynamic transport. These invisible damages, difficult to detect with the naked eye, not only directly reduce the rice yield and head rice rate but also lead to deterioration in stored grain quality and loss of market value, resulting in significant economic losses for enterprises annually. SRON, through in-depth research into the mechanical properties of rice grains and the mechanical mechanisms of storage and transportation processes, has developed a systematic solution based on terminal speed control, Janssen pressure model optimization, and the principle of kinetic energy dissipation.

Scientific Basis: From Particle Damage Mechanisms to Engineering Protection Parameters

Based on the mechanics of discrete particles such as rice, the R&D team at SRON has transformed the damage problem during grain storage and transportation into a quantifiable and analyzable mechanical model. Through systematic research on various mechanical forces acting on particles throughout the entire storage and transportation process, they have established a complete damage mechanism model and transformed the theoretical results into a protective parameter system that can be applied in engineering.

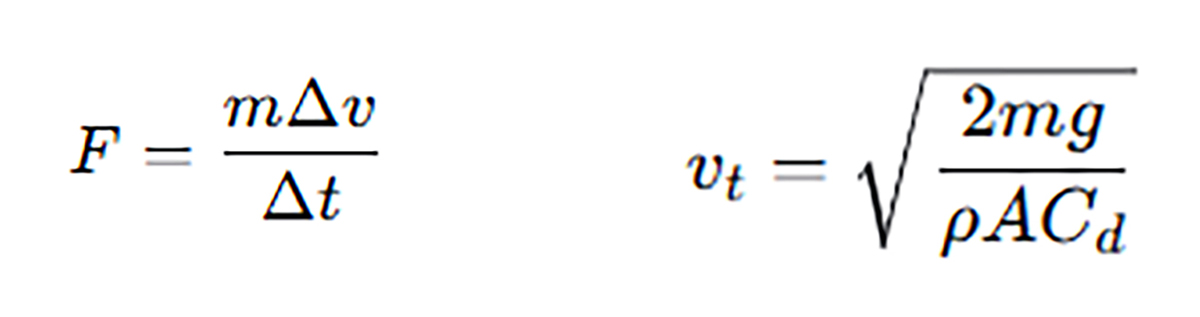

Dynamic impact theory formula

Static stacking theory formula

Core technology: Three-level mechanical protection system

Based on theoretical understanding, SRON has constructed a three-tiered protection system covering the entire storage and transportation process to systematically manage various damage risks:

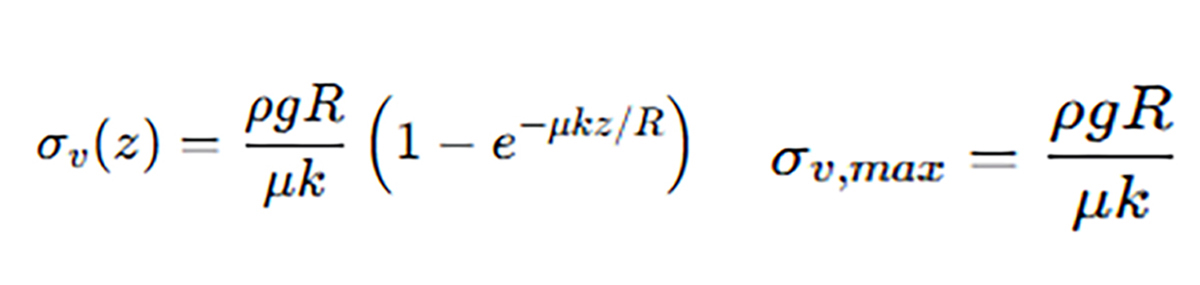

Dynamic shock buffering and dissipation

Key mechanical analysis shows that the terminal velocity of a single rice grain (approximately 2.5 × 10⁻⁵ kg) falling freely in the air is about 5.33 m/s. If it impacts a hard surface perpendicularly at this velocity (impact time approximately 0.001 s), the theoretical peak impact stress can reach 13.3 MPa, which is close to the typical compressive strength of rice (approximately 15 MPa). This is the mechanical reason for its breakage during a high-altitude fall.

The core of the protection lies in reducing the peak impact stress. Theoretical calculations show that when the impact time is increased from 0.001 seconds to 0.01 seconds, the impact stress can be reduced from 13.3 MPa to 1.33 MPa. Our design extends the impact time through buffer structures and materials, and combines a flow guiding device to change the particle landing posture to increase the contact area, disperse the impact force, and ensure that the actual stress is lower than the grain's compressive strength limit.

Static packing stress optimization

Under static storage conditions, calculations based on Janssen's deep silo theory show that the maximum vertical pressure on the bottom layer of rice in a 30m diameter silo is only about 0.22MPa, far below the compressive strength of a single grain. This indicates that the main mechanism leading to grain damage is not macroscopic static load, but rather stress concentration caused by limited contact between grains and dynamic shearing during unloading.

The coefficient of friction of the silo walls is generally between 0.3 and 0.5, and the coefficient of lateral pressure is controlled within the range of 0.4 to 0.6. Based on the mechanical laws of Janssen's formula, scientific material selection and structural design promote uniform vertical pressure distribution within the silo. The use of central integral flow unloading technology, coupled with a rational discharge port design, eliminates shear bands and severe inter-particle friction generated by funnel flow, preventing localized stress damage during static storage and unloading.

Dynamics control of the conveying process

Integrating drop impact and static pressure theories, the system manages multiple dynamic parameters: controlling the drop height and final velocity of particles based on the different physical characteristics of crops; optimizing the contact interface characteristics and extending the impact time by applying specific elastic and wear-resistant materials to the contact surface. By systematically regulating three key variables—impact momentum, contact area, and stress distribution—the system significantly reduces local stress peaks during transport.

Intelligent monitoring: Data-driven quality assurance

SRON has developed an integrated intelligent monitoring system that deploys a high-precision sensor network at key locations in silos to monitor parameters such as pressure distribution, temperature changes, and material flow at different depths in real time. The system combines variables such as grain moisture content and variety characteristics to construct a damage risk early warning model, providing data support and decision-making suggestions for warehouse management and operational scheduling. This enables a shift from reactive handling to proactive prevention, reducing mechanical damage caused by improper human operation.

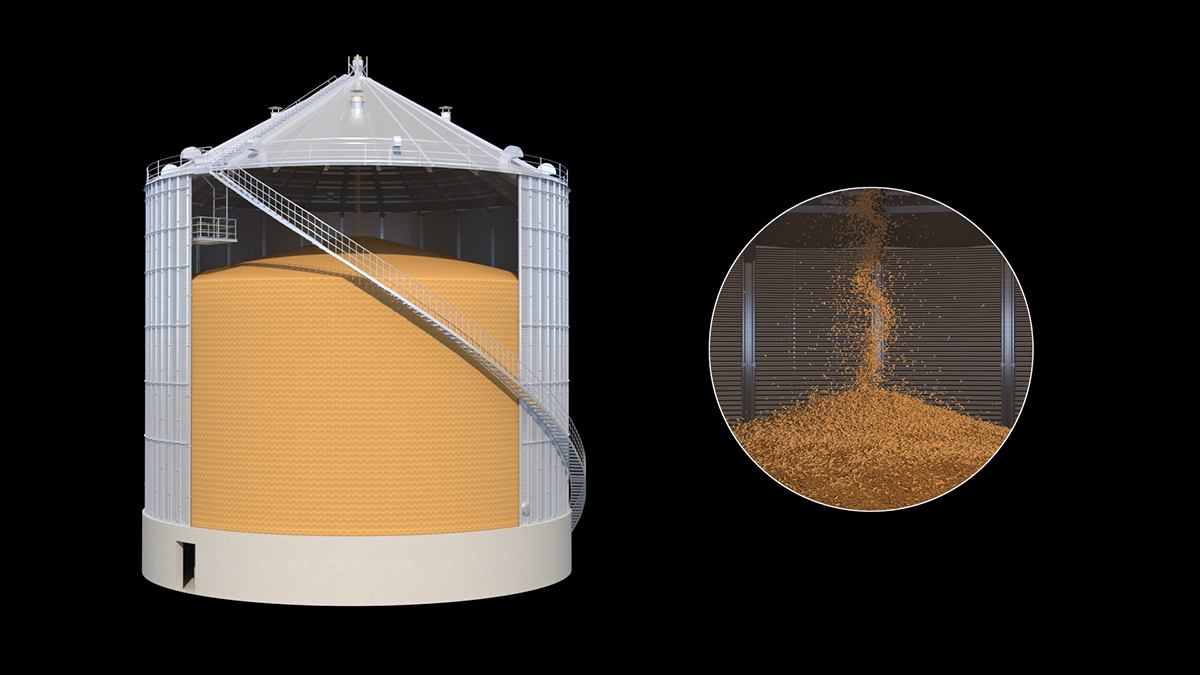

Global Practice: Combining Theory and Empirical Evidence

Currently, SRON has obtained over 100 patented technologies and has undertaken engineering projects in more than 40 countries and regions worldwide, constructing over 1,000 high-quality silos, earning unanimous recognition from domestic and international clients. The successful implementation of these projects not only validates the reliability of SRON's technological solutions but also contributes Chinese wisdom to global food security.

In the future, SRON will continue to serve customers globally, providing complete solutions covering design, manufacturing, installation and intelligent management, helping customers achieve a comprehensive upgrade from "reducing visible breakage" to "controlling hidden damage", and jointly promoting the development of the global grain storage and transportation industry towards a more efficient, economical and scientific direction.