Aug.28, 2017Keywords: flow type, Silo, adjustment

Silo is a kind of solution for storing grain, chemical fertilizer, cement and bulk material, widely applied to industry and agriculture field. There are two common failure forms of silo, material block and silo structure damage, both are closely related to the material flow type.

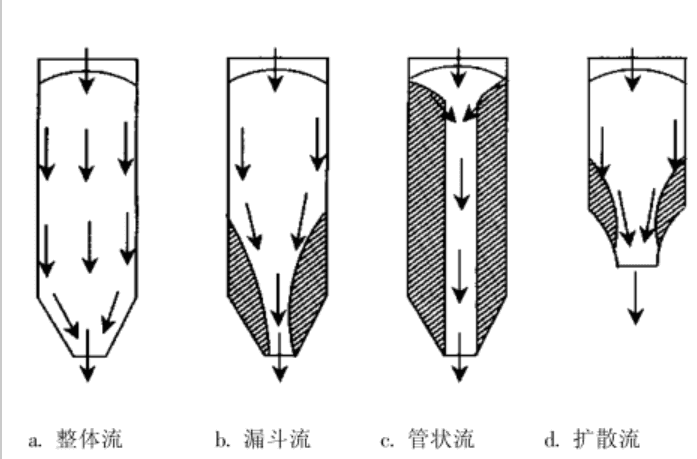

1. Flow type division

Funnel flow: When unloading, only the silo material within certain range above the discharge nozzle silo is in funnel flow, and the dead material area exists in the bin, there are dead material area in silo.

Diffusion flow: It is a deviant form of whole flow, which is the whole flow at the lower part and the upper part also become whole flow by diffusion.

2. Flow-type comparison

Geometrical factor: hopper inclination, discharge size, adopt the curve discharge hopper.

Effects of silo material and material physical properties: the inside and outside friction angle of material, silo wall rigidity, the density and compactness of the material.

Feeding form: central feed and disperse feed.

A: Adopt the central feeding form, make the material form cone top in silo.

B: Adopt the center discharge form with the biggest outlet opening so that the discharge outlet is unobstructed.

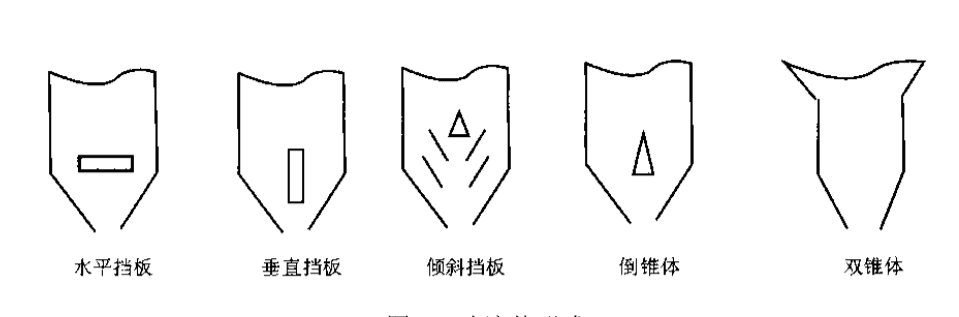

C: Use insert appropriately, install the straight clapboard, horizontal clapboard, or cone insert in the upper part of the hopper.

D: Adopt the arch drainage device for the non-free flow material.

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.