Insulated steel silo also called insulation steel silo is an important innovation in modern grain storage technology, playing a crucial role in ensuring grain safety and quality. With climate change and increasing demand for grain storage, traditional storage methods are no longer able to meet the requirements for long-term secure storage. The emergence of insulated steel silos effectively solves the problem of temperature fluctuations affecting grain quality. It provides a stable storage environment, reducing the impact of external temperature fluctuations on the stored grain, thereby extending the safe storage period and maintaining grain quality. Additionally, insulated steel silos can also reduce energy consumption, minimize losses during grain storage, improve storage efficiency, and provide reliable protection for grain security reserves.

Introduction to Insulated Steel Silos

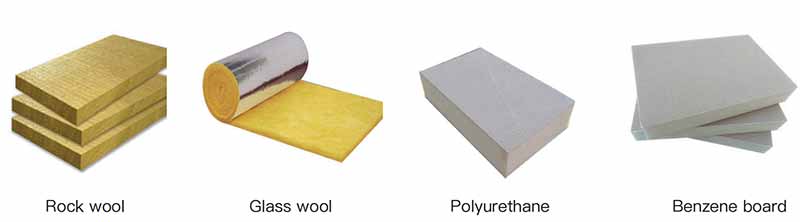

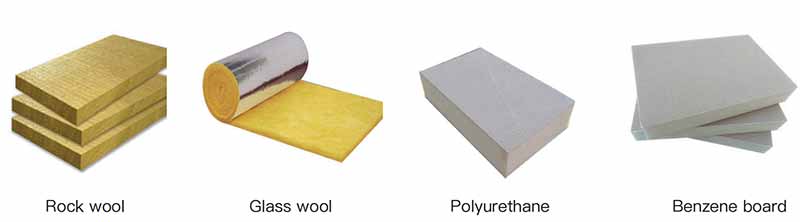

An insulated steel silo is an improved grain storage facility that adds an insulation layer to the traditional steel silo. Its main structure involves adding an insulation layer, filled with insulation materials such as polyurethane foam or rock wool, to the traditional steel silo, forming a complete insulation system. Compared to regular steel silos, the key characteristic of insulated steel silos is their excellent insulation performance. Regular steel silos have high thermal conductivity and are easily affected by external temperature changes, whereas insulated steel silos significantly reduce heat conduction through the design of the insulation layer, resulting in a more stable temperature inside the silo. This design not only effectively prevents condensation issues caused by temperature differences between the inside and outside of the silo but also minimizes quality changes in grain due to temperature fluctuations, making it particularly suitable for use in regions with large temperature differences, such as northern areas.

Insulated steel silos have several advantages and characteristics

Excellent insulation performance: The insulation layer effectively isolates external temperature changes, maintaining a stable temperature inside the silo and reducing the impact on stored grain.

Moisture and pest prevention: Good sealing and insulation properties effectively prevent moisture and pests from entering, inhibiting mold growth and pest infestation.

Fast construction: Modular design allows for quick construction and rapid deployment.

Intelligent management: Equipped with advanced monitoring and control systems, enabling real-time monitoring and automatic adjustment of parameters such as temperature and humidity, facilitating automated management.

Environmentally friendly and energy-efficient: Excellent insulation performance reduces energy consumption, aligning with modern green and sustainable principles.

Strong adaptability: Customizable designs based on regional climate characteristics and storage requirements.

Long service life: High-quality materials and scientific anti-corrosion treatments result in an extended lifespan, greatly reducing long-term operating costs.

Insulated steel silos play a significant role in ensuring grain storage safety

Firstly, they effectively control the internal temperature of the silo, reducing the impact of temperature fluctuations on grain quality. A stable low-temperature environment inhibits microbial activity and enzyme reactions, prolonging the safe storage period of grain.

Secondly, the excellent sealing performance of insulated steel silos prevents the intrusion of external moisture and pests, reducing the risk of mold and pest infestation.

Thirdly, insulated steel silos can minimize grain condensation issues caused by temperature changes, avoiding quality problems resulting from localized dampness.

Fourthly, insulated steel silos can be equipped with advanced monitoring systems to monitor parameters such as temperature and humidity inside the silo in real-time, promptly identifying and addressing potential safety hazards.

Lastly, insulated steel silos provide good ventilation conditions, allowing for the timely discharge of heat and moisture generated during storage, preventing self-heating and mold growth in grain piles.

These characteristics make insulated steel silos an essential facility for ensuring grain storage safety. As a critical component of modern grain storage technology, insulated steel silos play an irreplaceable role in guaranteeing grain safety and quality. Through their excellent insulation performance, moisture and pest prevention capabilities, and intelligent management, they effectively address many challenges faced by traditional grain storage methods. Insulated steel silos not only extend the safe storage period and maintain grain quality but also reduce energy consumption and improve storage efficiency. In the face of climate change and increasing demand for grain storage, insulated steel silos provide reliable technological support for ensuring national food security. With continuous technological advancements and accumulated application experience, insulated steel silos will play an even more important role in the future of grain storage, making significant contributions to ensuring food security and promoting sustainable agricultural development.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)